CLIENT:

Various

LOCATION:

Deacam Factory - Bayswater, Victoria

FAST FACTS:

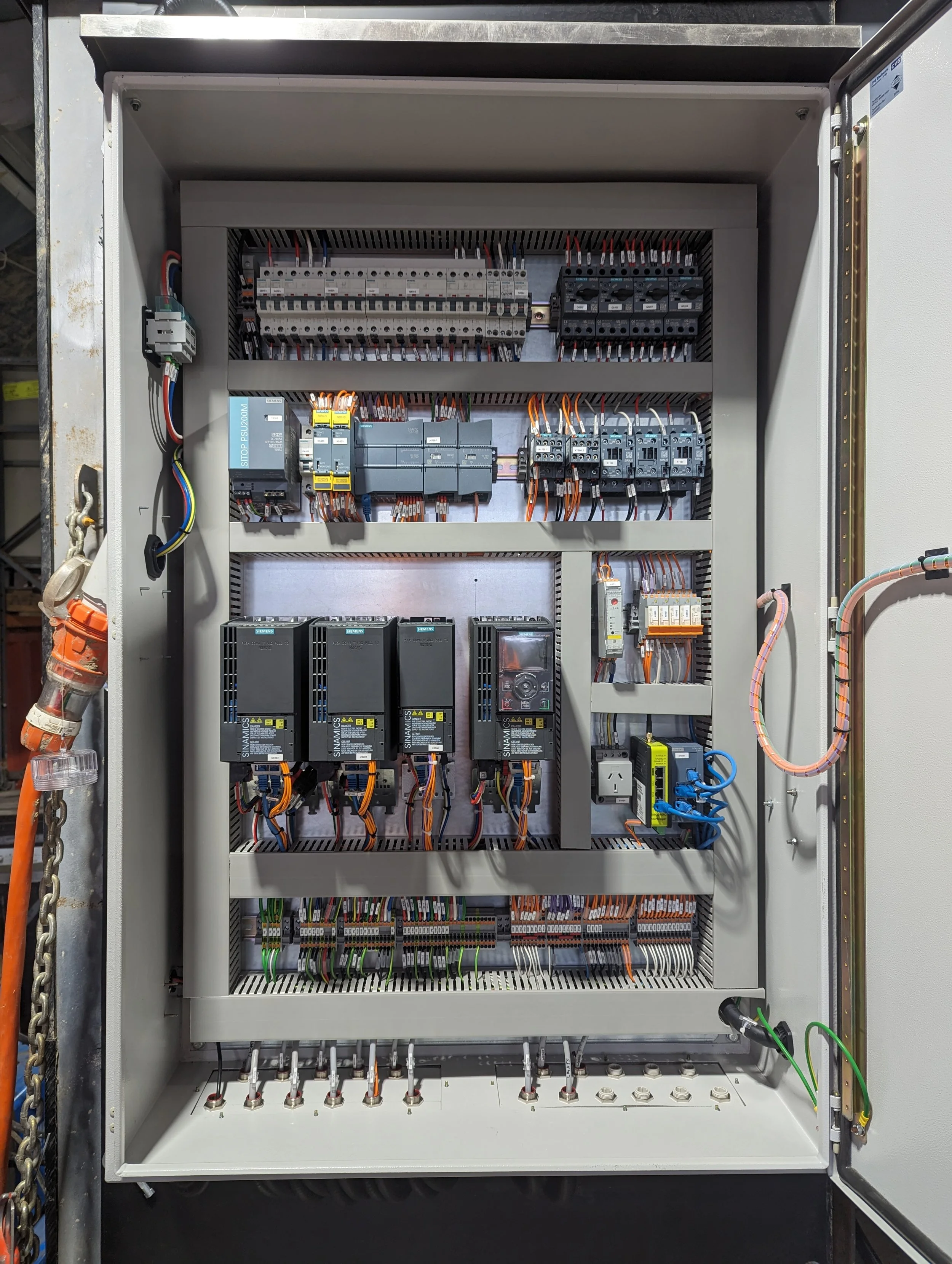

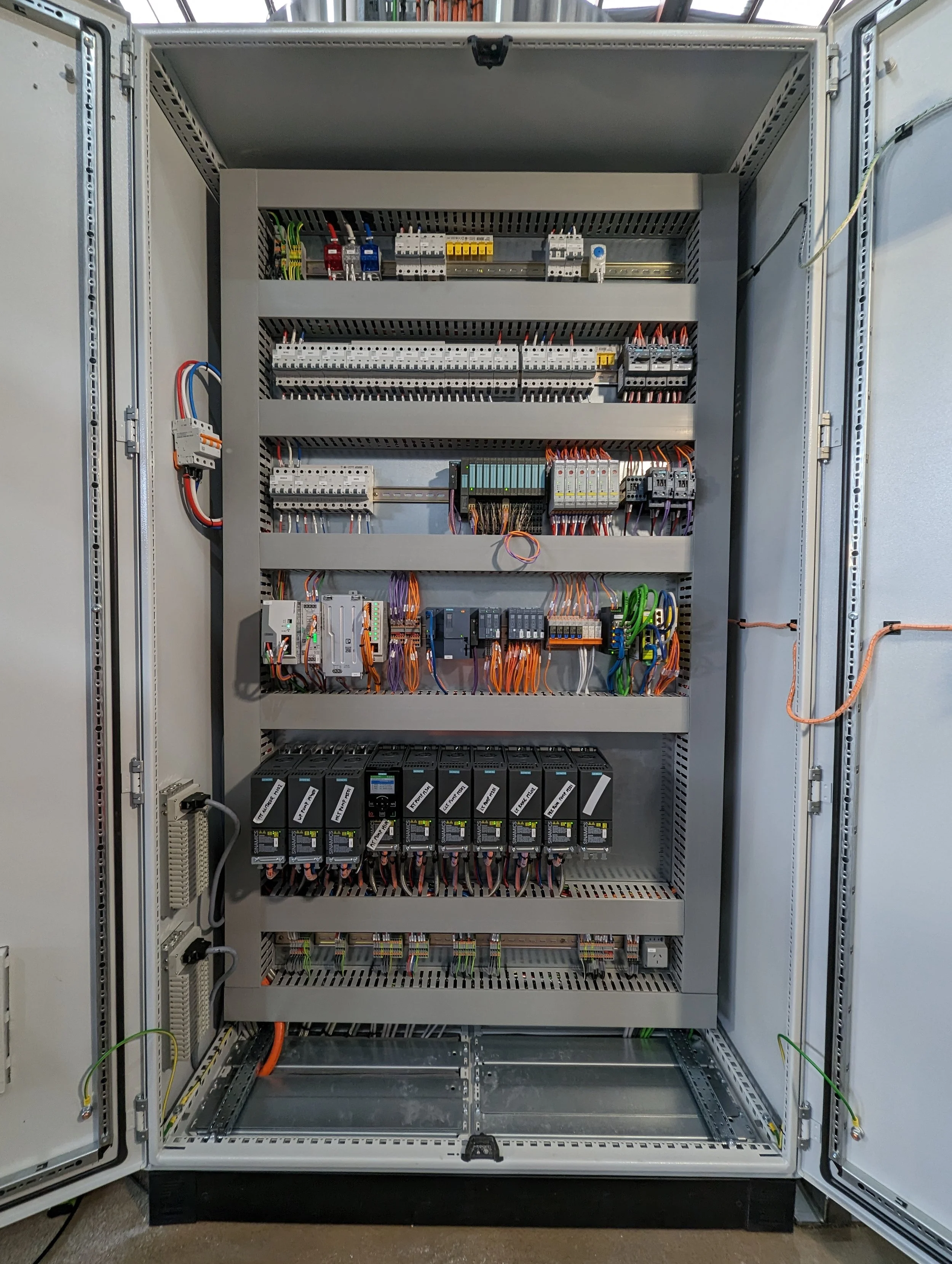

At Deacam, we consider the interpretation and understanding of schematics, including the ability to efficiently and effectively wire control panels, an essential part of an electrical apprenticeship. Our panel building shop's training group enables apprentices to learn on the job under the supervision of experienced tradesmen. We are proud that every apprentice who graduates from Deacam does so with the key skills of reading, writing, and interpreting detailed schematics, as well as transforming these designs into complex, high-quality installations that meet our rigorous standards.

Description:

At Deacam we maintain a fully stocked and equipped panel building workshop at our head office in Bayswater, Vic. Equipped with automated CNC cutting and marking, 3D printing and more, Deacam is sure to deliver high-quality, precision-engineered panels tailored to meet your specific needs.

Our team of skilled technicians and engineers work diligently to ensure every project meets the highest standards of excellence, providing reliable solutions for a wide range of industrial applications.

Services provided:

Turnkey service from concept to out commissioning

Functional description development

Schematic development

Risk assessment

SIL/PL rated safety system design and construct

Panel layout drawings

3D panel renderings

Hardware specification

Retrofit/interface with existing equipment

Setup, programming, and commissioning

PLC

VSD

Soft starter

Motor starters

HMI

Safety relays/controllers

Retrofit/interface with existing equipment

Modular/expandable installations

Remote touch screen control

Factory Acceptance Testing

3D Printing

CNC cutting and marking